Troubleshooting Pumps

By Diane M. Calabrese / Published July 2020

Water mains break, water towers topple, and disoriented utility workers mistakenly shut off the water to the house that’s not under construction (i.e., yours). Consequently, most of us have turned on a tap to discover the flow is gone.

Pressure is a wonderful force, capable of doing all sorts of good things, from flattening asphalt to puffing up clothes. When it’s expected to be there and it’s not, work is interrupted.

Reliable pumps are a must in pressure washers. If a pump falters or fails, the machine it supports cannot be used, and a contractor sustains a loss of time and money.

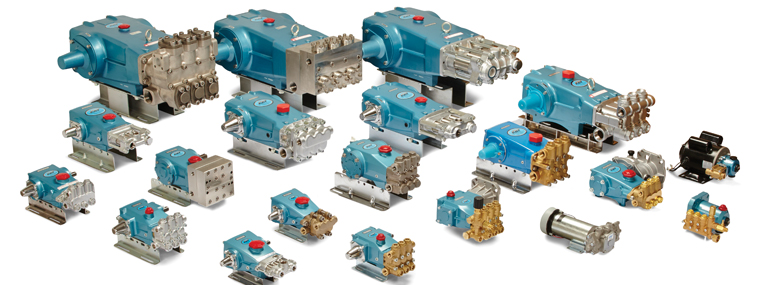

Fortunately, our industry is bolstered by pumps crafted by manufacturers that understand the needs of end users, which includes pumps that are as reliable as they are strong. More fortunately, two experts in pumps were willing to share with us some of their considerable expertise on the topic of troubleshooting pumps.

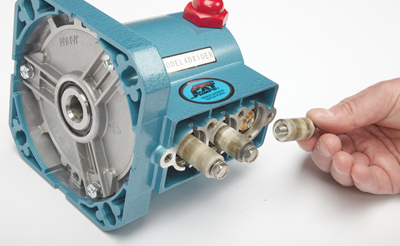

Reassembly of Plungers.

Indeed, the experts confirm that although the pump may be the suspect, it is most often not the culprit. Yes, troubleshooting has a lot in common with detective work. The place to begin is by being open to all possibilities with a commitment to assess a situation in a methodical way, with no jumping to conclusions.

Chris Schuelke, business development manager at Cat Pumps in Minneapolis, MN, and Ben Hagemann, general manager at American Pressure Inc. in Robbinsdale, MN, are the experts providing responses to our questions.

CLEANER TIMES (CT): Is there one type of pump that is more vulnerable to problems than any other type?

Schuelke: Axial pumps that are used on low-cost pressure washers are much more vulnerable to problems than triplex plunger pumps.

Hagemann: A pump that is being used incorrectly. Pumps must be run in accordance with how they are designed to be used. Belt-drive pumps will outlast direct-drive pumps because they are spinning slower and are isolated from the vibration and heat of the engine, but direct-drive pumps are lighter in weight, which lightens the weight of a pressure washer for easier loading/unloading.

CT: If a pump stops working, should the owner of the machine even try to troubleshoot?

Schuelke: It is common to initially blame the pump when a system isn’t working, but much of the time the issue is located elsewhere. Users should troubleshoot the system as a whole in order to determine what is causing the problem. For example, low pressure can be caused by a number of things like a worn nozzle, insufficient inlet supply, worn pressure unloader, etc. There are plenty of pressure washer troubleshooting guides online to help with the troubleshooting process. [Schuelke’s company offers a troubleshooting guide at its website. See https://www.catpumps.com/troubleshooting.]

Hagemann: Most of the time it isn’t the pump that caused the machine to stop working. Clogged nozzles and unloaders are more common than complete pump failure. The pump moves the water, the unloader directs it where to go, and the nozzle makes the pressure. If the symptom is a sudden loss of pressure, usually the pump is just fine. Try these things: check first for debris in the nozzle, which might be indicated by an unfamiliar spray pattern; verify the correct size nozzle is in use; verify there is water reaching the pump and that the inlet plumbing is in good order. On machines that draw from a tank, whether attached or auxiliary, the pump will pull water in under a vacuum.

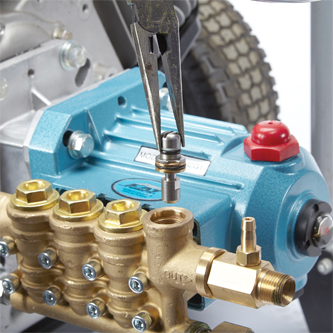

Servicing the Valves.

Any breach in a tank draws in air. A very small amount of air will cause cavitation and slight vibration, and it will be causing damage to the pump and other components. A larger air leak, like an open upstream chemical injection valve or leaky pump protector, could cause no pressure at all. The pump isn’t able to move water because a bit of air is coming into the pump.

[Among the many tools Hagemann’s company provides at its website is a nozzle chart that simplifies matching nozzle size to psi and spray coverage. See https://

https://www.americanpressureinc.com/wp-content/uploads/sites/47/2017/10/Nozzle-Chart.pdf.]

CT: Which sort of pump failure should have the owner immediately taking the pump to the nearest service center?

Schuelke: That depends on the mechanical capabilities, comfort level, and time available to the owner. Routine maintenance of triplex pumps, used on pressure washers and car washes, is relatively simple. Replacing seals and valves in a pump can be done in under an hour by an experienced technician, but it can take a bit longer for those who have never done the repairs. There are advantages to having a service center work on the pumps, including time savings and the assurance repairs are done correctly.

Hagemann: Any time there is a failure or lack of pressure, it is good to speak to your local distributor who knows pressure washers and will get you the right advice and correct parts for your machine…A professional distributor knows the equipment and how to keep it running safely. Why did it fail, and how can the same failure be prevented? These are factors we evaluate on almost every machine we repair. Improving plumbing to the pump is one area that greatly increases pump longevity and system performance with very little cost.

High Pressure Seals.

Some pump symptoms should be addressed immediately. One is any leak from the valve caps on the pump. Over pressurizing a pump by deadheading it and freezing a pump are two things that can damage the integrity of the pump manifold; even though the pump could still be working, it should be replaced.

The manifold itself can be stretched by deadheading or freezing, meaning the check valve caps aren’t held in place properly; the drip or leak of a bulging O-ring would suggest this and is a warning of a potentially very dangerous situation. The force pushing on a check valve cap in normal operation can turn the cap into a dangerous projectile if it is not held in place correctly.

CT: Is there a way to avoid most issues with pumps? For example, should an owner be aware of the pump’s longevity and replace it before its natural lifespan ends?

Schuelke: Maximizing pump life starts with choosing the best pump for the application. A slower running belt-driven pump will last longer than a direct-drive pump. A system running several hours a day should be sized accordingly.

It is important to operate our pump within its rated performance. This not only includes flow and pressure but also includes inlet conditions, temperature, duty cycle, and liquid compatibility.

Hagemann: The best way to avoid issues is to give your pump a good supply of cool and clean water and follow the recommendations of pump oil changes from the manufacturer.

Servicing the Unloader or Regulator.

Many pressure pumps are capable of drawing water out of a tank and generating a certain level of vacuum; manufacturers of the pump will publish this data on their pumps. When a machine is set up on a trailer to draw out of a tank, the vacuum should always be tested with a gauge and modifications made to keep it as low as possible. Straight runs of hose going into the pump manifold, big enough fittings, short lengths of hose, and minimal turns through filters and fittings are important. The foregoing will enhance the longevity of seals, aka packings, and check valves, which will wear gradually instead of exhibiting a complete failure. A dealer can look at worn seals and valves and determine the cause—e.g., lack of water, running dry—which will help the owner avoid a repeat of the issues.

CT: If you had a checklist for troubleshooting a pump issue, what would be the first entry on it?

Schuelke: The first thing to check is the inlet conditions to the pump. Make sure water is turned on, the filter is clean, and the hose isn’t kinked.

Hagemann: If I had a checklist for troubleshooting “no pressure” from a pressure washer—often called a pump issue—I would say two answers are that either the nozzle or the unloader needs to be replaced. There is a difference if your pump stopped working from one day to the next or over a longer interval. If a pump sits for weeks or months, check valves can stick shut and just need to be opened for the pump to work again.

CT: What else should we have asked?

Hagemann: One of the observations I have had is that when you don’t utilize the full design performance of a pump, it will often last longer. Some of the pump manufacturers seem to overbuild their pumps, and others seem to build the pumps just to make specifications. To compare pumps isn’t always as simple as pressure and flow. Many things must be considered, such as rpm, bore, stroke, oil capacity, and seal material. A higher speed pump can have a smaller oil end because each revolution is seeing less work. Talk to your local CETA distributor, who can talk through differences with you so you know what you are getting and can make sure it is right for your needs.