“Stepping Away from the Wand,” Part Two

How to Train Others to Do the Work That You Do So Well

by Mike Dingler / Published January 2022

Editor’s Note: Part one of this series was published in the December 2021 issue of Cleaner Times. If you don’t have that issue, the article can be read online at https://www.cleanertimes.com/magazine/cleaner-times-articles-2/stepping-away-from-the-wand-part-one-why-you-should-not-do-all-the-work. Part three, which will be the final installment in the series, will be published in the February 2022 issue of Cleaner Times.

In last month’s article we learned why we should not do all the work and why our business needs us to find employees to help us scale our business. This month we will get our game plan together on how to structure our business to employ technicians, office managers, salespeople, and more.

One of the main things we struggle with as entrepreneurs and business owners is ego. Ego can make or break us in business, and having an inflated ego with employees is a disaster. Speaking of employees, as Dave Ramsey says, “Employees come in late, leave early, and most likely steal while they are there.” Terminology such as “employees” is being replaced with more appealing words like “team members,” “technicians,” and “sales associates.” What’s the difference? How you treat the human beings who are working in your business. It is better to have two team members rather than four employees. Employees are someone you hire to do a task, and the relationship between employer and employee is very cold and impersonal. That may have worked in the past but not now. In the business world we live in, everything has changed since COVID-19. With all the government handouts, people now get to choose whether or not they will go to work, where they will work, who they will work for, and what they will do while at work. In some states, auto technicians have found better pay at McDonald’s. Speaking of McDonald’s, since raising the minimum wage some public safety departments have had to raise the starting pay of firefighters and police officers to compete with fast food and other industries.

To some employers in some states, the world seems to have turned inside out. The exterior cleaning industry is no different. To find good technicians we must make our business look very attractive or at least more attractive than McDonald’s. Think that’s easy? Think again. Ray Kroc isn’t well known for creating McDonald’s—the McDonald brothers, Richard and Maurice—did that, but Ray franchised what they couldn’t. How did he do that? He made SOPs (standard operating procedures) for everything. He assumed that his freshly-hired staff wouldn’t know anything about the fast-food industry because he was currently creating it. Fast food did not exist until McDonald’s made it so well known by its SOPs and processes. Proper paperwork gave everyone in the kitchen an assignment and a plan, and along with everyone at the counter who also had an assignment and a plan, a legacy was born. Your exterior cleaning business may never be nationwide (unless you want it to be), but it will be able to scale to whatever level you are comfortable at if you implement structure and order within your business with SOPs and systems.

So where do you start? It’s very simple really. Assume a person you hire has never done the job before (some employers prefer to have technicians who have never washed before as they don’t have to fix bad habits), and start a document that you will name “standard operating procedures.” If you are not computer savvy, you must be. It’s 2022 and you own a business, so get with the times. Start a document on your phone in notes; start one on your ipad, laptop, or whatever device you want; but the key is to start the document. (Just like going to the gym, nothing happens unless you show up. Most people will never start the document.) Now add how you do the things you do to the document every day you are out washing and every time you have a break. Remember, you are training someone with zero knowledge of the pressure washing industry besides “they washed their grandpa’s house one time with a Ryobi.” Make a process and a procedure for the following at a minimum:

- Daily morning meeting: review the work before you do the work.

- Daily truck check: make sure you have everything you need before you leave the shop.

- How to set up the equipment

- How to troubleshoot the equipment

- How to operate the equipment

Anything else you need to document. Assume the lowest experience level possible and type away, as there is no going overboard. The more detail oriented you are, the more it will help in the future for insurance and workers’ comp. rates/claims. (bubbl.us is a great tool for making flowcharts, if you wish to incorporate them into the document)

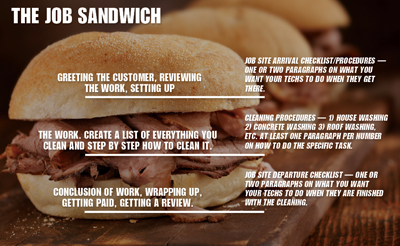

The Job Sandwich

The Job Sandwich

A sandwich has two pieces of bread and meat in the middle. A job has a beginning and an ending, and the meat is what you are washing. The bread never changes as it consists of a top and bottom piece.

If you complete the items above, you are well on your way to having an electronic file of your SOPs to email to your new hires (along with your welcome letter and safety manual) before their first day of work. This does wonders as they have already familiarized themselves with your processes and already know in their minds what they should be doing with their hands. The more detailed you were in your documentation, the better the technician will do on his first day and all subsequent days. Good habits are formed from knowing the correct way to wash something before the pressure washer is used, not just a spray and pray that some new hires will inevitably do. If you want someone to rinse and post treat the concrete after it is surface cleaned, and then find out the tech didn’t post treat, whose fault is that? If it wasn’t in the SOPs, it’s your fault. If it was, then he did not read the SOPs or did not retain the information because you did not enforce retention of information (think a once-a-year online test over the SOPs made in Google docs); it’s your fault. Anything that happens in your business is your fault, so document every process you want done in your SOPs. No detail is too detailed. If you do all this correctly, you will now have formed your businesses SOPs, but as always, everything changes. Update your SOPs so they stay up to date with the chemicals and processes your business is using.

SOPs and the safety manual go hand in hand so let’s review how to make a safety manual.

Safety Procedures—Take pictures of all personal protective equipment (PPE) you will provide, and describe what PPE you want your technicians to wear and when they should wear it (i.e., anytime chemicals are in use eye protection is mandatory).

Describe the proper way to don and doff any equipment and describe how to use and inspect harness systems and ladders. The greater the detail you provide as far as above ground operations go, the easier time you will have if someone gets hurt and workers’ comp gets involved.

Describe how you want the truck to be parked, road cone use, etc. Your safety manual should cover any situation your technician could find himself in while working for your company and what to do to stay safe at all times. (i.e., do your technicians know what to do in case their truck breaks down as far as roadside

safety is concerned?)

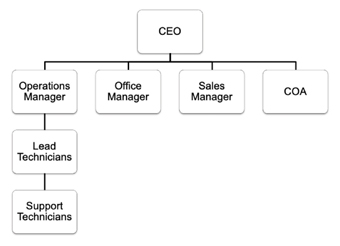

Last but not least you should type out a welcome letter, a short, normally one page document on how you got started, what you went through to make it to where you are now, and your vision for your company’s future. What do you see your business like in one year? Three years? And five years? Narrate all these scenarios for your new hire to know your plan and what’s in your head. Future technicians want to see where you want to be and how their work will help everyone get there. Make the one, three, and five-year scenarios seem very appealing to your new hire. Make the new hire feel like he is joining an up-and-coming business full of potential to advance both his position and pay. Also make an organization chart (see example below) and introduce your mission statement, which is a short (usually one to three sentence) declaration of your business and what it stands for (google “create a mission statement for my business” for more information).

Last but not least you should type out a welcome letter, a short, normally one page document on how you got started, what you went through to make it to where you are now, and your vision for your company’s future. What do you see your business like in one year? Three years? And five years? Narrate all these scenarios for your new hire to know your plan and what’s in your head. Future technicians want to see where you want to be and how their work will help everyone get there. Make the one, three, and five-year scenarios seem very appealing to your new hire. Make the new hire feel like he is joining an up-and-coming business full of potential to advance both his position and pay. Also make an organization chart (see example below) and introduce your mission statement, which is a short (usually one to three sentence) declaration of your business and what it stands for (google “create a mission statement for my business” for more information).

If you document everything correctly and ensure your technicians have read the material, you are on your way to trusting others to do the work the way you do it and obtaining the same results as if you were there on the truck yourself. A lot of business owners simply adopt “the learn as you work” training method because that is what was done to them. We can do better as business owners today; we must if we want to be successful. We must teach our people not to just hold ladders and water down plants, and with a written plan that they read before their first day of work, we can achieve great results.

“But I can’t find good help.” Maybe good help can’t find you! If you were to go on a cruise, would you go on one that was just going to cruise around the ocean? Or would you go on one that had a destination? Your future technicians, office managers, operations managers, and so on need to see your destination, or they may not want to go with you. If your competition has a plan, a playbook, a route, and a process, then the good, detail-oriented, hard-working technicians go to them. If you want people to work for you with a detail-oriented, perfectionist-type mentality, then you must run your business the same way to attract those people. If you don’t have a mission statement, welcome letter, and safety and SOP manuals, you are simply floating around the ocean, and not that many awesome people will ever go with you.

With a typed-out document that contains an introduction letter, mission statement, SOPs, and safety manual in place, this document will set the standard and the tone for your technicians and other staff in the future. Update the document often and save the document as a PDF when you send it to your new hires. If your job sandwich and other technical operations are something you would like to protect, a nondisclosure/noncompete article may be in order, but remember this: most people can find out how to clean anything on the internet. YouTube videos and “gurus” can be found all day long on roof cleaning, etc. It is not the process of cleaning that is proprietary information but rather your process and procedures that may be. If you are worried about someone coming to work for you and then taking your processes and starting their own business, review the first of these series of articles in last month’s issue and remember that a lot of people simply want to be employed, not own the company that employs them. Your future team members need to see where you are going, where you have been, and how you will get to your destination. Just like McDonald’s, it is your job to put standard operating procedures in place to ensure the journey to your destination is a good one full of money-making opportunities and fun times for your team. Now that we have reviewed why you should step away from the wand and how to get others to do the work like you do, in next month’s article we will discuss how to further

systematize and automate your business so that it runs smoothly, without you on the truck!

Mike Dingler is owner of Firehouse Pressure Washing, Soft Washing, and Roof Cleaning Inc. He has been in the exterior cleaning industry since 1996. In addition, his book, Small Service Based Business Basics: How to Run Your Business and Not Let Your Business Run You, is available on Amazon. For more information, call (770) 468-0014 or visit www.firehousepowerwash.com.