Softwash—Metering vs. Batching

What Is The Difference and Why Does It Matter?

By Pete Gustin / Published July 2019

Softwash can be described as the perfect bridge between pressure washing and pest control in that the objective is to clean or eradicate a live organism—mold. For that reason, softwash equipment generally resembles a pest control sprayer more than a pressure washer, but there are several factors that make softwash equipment unique. First is the need to adjust chemical concentration based on the level of infestation and the surface material being cleaned. Second is the need to completely isolate the chemical from fresh water, which is used to pre-soak and rinse a job site. Third is the corrosive nature of the chemical—in this case, sodium hypochlorite (SH, also known as NaOCI).

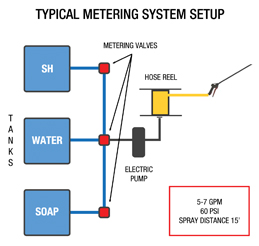

Metering and batching are two methods used to accomplish these goals. Metering allows you to keep fresh water, SH, and soap in separate tanks and dial in a specific solution for various job types, such as roofs, siding, or driveways. This can potentially lead to more jobs in a smaller geographic area and less money spent on the drive time. Electric pumps with a pressure switch are ideal for metering as they can suck the amounts of each chemical needed and simply turn off when the trigger or wand is released. In addition, the electric pumps used for metering are quiet and can be used in residential neighborhoods that have noise restrictions in the morning and evening. The disadvantages are that the electric pumps do not last with sodium hypochlorite and do not offer the flow and pressure required for quickly pre-wetting and rinsing. Therefore, either a booster pump or pressure washer is usually added on top of the already expensive equipment. In addition, minimal spray distance means more ladders and/or walking on roofs.

Metering and batching are two methods used to accomplish these goals. Metering allows you to keep fresh water, SH, and soap in separate tanks and dial in a specific solution for various job types, such as roofs, siding, or driveways. This can potentially lead to more jobs in a smaller geographic area and less money spent on the drive time. Electric pumps with a pressure switch are ideal for metering as they can suck the amounts of each chemical needed and simply turn off when the trigger or wand is released. In addition, the electric pumps used for metering are quiet and can be used in residential neighborhoods that have noise restrictions in the morning and evening. The disadvantages are that the electric pumps do not last with sodium hypochlorite and do not offer the flow and pressure required for quickly pre-wetting and rinsing. Therefore, either a booster pump or pressure washer is usually added on top of the already expensive equipment. In addition, minimal spray distance means more ladders and/or walking on roofs.

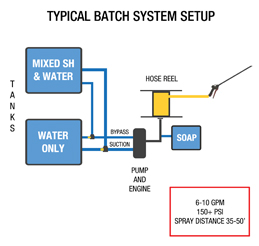

On the flip side, using a semi-hydraulic diaphragm pump on a gas engine means ultra-fast pre-wetting and rinsing and a spray distance of 40–50 feet, keeping ladders and roof walking to a minimum. These pumps also last much longer and are easily rebuildable. The downsides to this system are that the solution being sprayed must bypass back into one of the tanks, contaminating its contents, so you have to carry a premixed batch and focus on specific jobs. In addition, the added noise may limit spray time in certain neighborhoods, but the boost in productivity should more than make up for that.

In the end, there is no wrong answer. It comes down to job selection, crew size, and equipment budget. One company may choose to focus on roofs, using a four or five percent batch, while another may want to have the versatility of doing roofs, siding, or driveways. Experience level may also play a part. One business owner may trust his crew to dial in the proper solutions, while another may want to stick with one set of instructions.

In the end, there is no wrong answer. It comes down to job selection, crew size, and equipment budget. One company may choose to focus on roofs, using a four or five percent batch, while another may want to have the versatility of doing roofs, siding, or driveways. Experience level may also play a part. One business owner may trust his crew to dial in the proper solutions, while another may want to stick with one set of instructions.

When it comes to cost, electric pumps are much less expensive, but they don’t last as long or perform as well. Some operators prefer to just switch out defective pumps and consider it a cost of doing business, while others prefer to replace valves or fittings once in a while in order to have the performance and productivity of a gas engine unit.

Regardless of whether you decide to meter or batch, softwash is in high demand. Pressure washing companies, lawn care companies, and window cleaners are cashing in on their existing routes or expanding into the booming market, and there is no end in sight.