Reap Positive Results with a Maintenance Schedule

By Diane M. Calabrese / Published June 2023

Wouldn’t a stack of business positives be nice? Try this one: lower operating costs, less downtime, and more tranquil employees. (That tranquility results from not having to contend with breakdowns.)

A maintenance schedule may sound as exciting as a high-school class schedule. Adherence to a structured plan—in either context—is the surest way to reap positive results.

“Maintenance on your equipment will predict the success of your company,” says Missy Ordiway, business development manager at Deco Products Inc. in Denver, CO. “If you aren’t performing regular maintenance on your equipment, the outcome of your jobs can be less than excellent.”

Along with the risk of diminished product quality, there is also the risk of time wasted. “When you aren’t performing maintenance regularly, your equipment could malfunction at inopportune times, such as on a large job or a job with a deadline,” explains Ordiway.

Just leaping in and establishing a maintenance schedule that seems workable is admirable, but there’s a better place to begin. “Unless you have experience with the equipment you are using, you are reliant on the manufacturer’s recommendations,” says Ordiway. “Their recommendations work a large percentage of the time.”

Also, take advantage of the expertise available from vendors. “I suggest talking to a local repair shop that has a lot of experience to know what parts to have on hand since not all replacements can be planned maintenance,” says Ordiway.

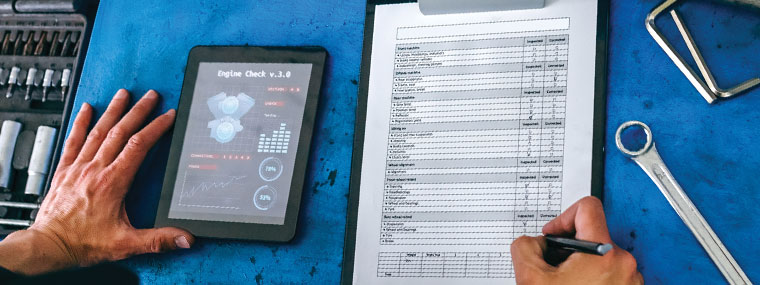

In addition use technology to the fullest extent possible. “Using a computerized maintenance management system, or CMMS, will help you maintain a schedule and track the maintenance performed,” says Ordiway.

With a maintenance schedule, the owner of a business stays in control, avoiding wholly preventable disruptions. We may be in the industry realm of manufacturers, distributors, and contractors, but the need for scheduled upkeep antedates this industry or any industry.

Push any part of a system too hard, neglect repairs, or both, and you invite trouble. Maintenance derives from two Latin words that together convey the meaning to hold in hand.

A company with a rigorous maintenance schedule definitely “holds in hand”—controls—processes better than a company with a take-what-comes and deal-with-it-then approach. Yet the “don’t fix it unless it’s broken” aphorism does not find many takers in 2023.

Business processes are too complex, and the industry tools are too sophisticated to not attend to maintenance with the same attention given to financials. Not feeding and watering a horse on schedule could lead to a very bad outcome, for instance. Rest for a horse also had to be scheduled. Anyone who has seen the

film The Searchers (1956) remembers well the scene when Ethan (John Wayne) tells the young Martin (Jeffrey Hunter) that the horses must be rested and fed.

Determined to try to do the impossible, Martin rides ahead. In the process, he kills his horse.

Partners

In many ways, scheduled maintenance is about doing the possible. Maximize performance of equipment. Minimize downtime as well as costs associated with repair and replacement.

If 19th century endeavors hinged on person-to-person advice, such as “get that horse’s shoe fixed,” the first two-thirds of the 20th century relied on the tight pairing of mechanics and the machines they maintained. Boiler room operators, for example, were always on the job, assessing and modifying in real time.

As the size of machines scaled down and their dependability improved at great speed, the need for one individual to be attentive to a piece of equipment at every moment of operation began to fade. Technology made things easier to do with fewer people and eventually took most employees farther away from the functioning parts of equipment.

The separation in space was a good thing for safety, but the lack of proximity made it easier to overlook what was happening. Fortunately, the same technology that takes people out of the picture can put them back in. Take advantage of it.

“There are software systems available to help track regular, scheduled maintenance tasks and/or preventive maintenance items,” explains Bryson Sharp, design engineering manager at Northern Tool + Equipment in Faribault, MN. They are a good way to ascertain that a maintenance schedule is being followed with exactness.

Overstating the significance of ensuring all machines are in optimal condition is not possible. “If a key

piece of equipment goes down for an unscheduled repair or maintenance, it can cause a gap in productivity and impact profitability,” says Sharp.

Given time, lapsed maintenance yields the inevitable. “Eventually a critical piece of equipment will go down and require maintenance,” explains Sharp. “Having a preventive maintenance plan or schedule will keep the equipment in good working order and will help to minimize these occurrences and disruptions.”

The scope of a maintenance schedule encompasses all tangibles tied to a business. From vehicles and parking lots to portable electronic devices, everything should be on a maintenance schedule.

O&M, the shorthand for an operation and maintenance program, does something more than ensure top performance of the company. It also cuts energy use. There’s no escaping the fact that for a variety of reasons, almost everyone is looking at energy use. Businesses want to keep expenditures to a minimum, regulators want huge reductions in emissions, and utility companies aim to stabilize and strengthen their grids and delivery.

Every kind of company benefits from a maintenance schedule. That includes contractors, irrespective of their size.

Best Practices

Consider what others do that works. That’s the advice from George Clarke, owner of Outdoor ProWash LLC in Nashville, TN, and a former president of the UAMCC.

“What are some of the best practices for developing a comprehensive maintenance schedule that considers all critical maintenance tasks and ensures they are completed regularly?” says Clarke. Answer that question to get a viable approach in place.

[Professional organizations such as UAMCC, PWNA, CETA, and WJTA give their members a big boost in the identification of best practices. That’s because identifying and adhering to best practices is part of the purview of each.]

“A maintenance schedule should be considered an essential part of business planning in the cleaning in-

dustry,” says Clarke. “Regular maintenance can prevent breakdowns, prolong the lifespan of equipment, ensure a safe working environment, and minimize downtime, all of which are critical for success and profitable business.”

How long has it been since the O&M program has been given a serious look? That serious look includes assessment of the current program with identification of checks that must be added (or in some cases subtracted because a piece of equipment is no longer in service). Assessment is followed by implementation and documentation of the new O&M.

A methodical approach—assess, implement, and document (AID)—undergirds every robust maintenance schedule. AID, the acronym, is it precisely.

“There are several ways to double-check or verify that a maintenance schedule is being followed,” says Clarke. “One way is to conduct regular inspections and audits to ensure that maintenance tasks are being completed as scheduled. Another way is to keep a record of maintenance activities and review them regularly to identify any missed or incomplete tasks.”

After that, it’s about ranking tasks. Checks, rechecks, and interventions are not all equal. “One of the most overlooked aspects of developing a maintenance schedule is prioritizing tasks based on their level of importance,” says Clarke. “Often, businesses tend to focus on routine maintenance and neglect critical maintenance tasks that can have severe consequences if not performed regularly.”

Clarke explains that there’s very little, if anything, that cannot be scheduled. “Generally, all parts of a facility or equipment can be fitted into a maintenance schedule. However, some components may require more frequent or specialized maintenance, and businesses need to account for these differences when developing their maintenance schedule.”

Good recommendations from our sources, but are the live and learn (the hard way) types still out there? Yes, of course, although dead batteries, not dead horses, indicate them in this century.

Those who shun the maintenance schedule have adopted a type of maintenance categorized as “reactive” (or sometimes “corrective”). They do maintenance eventually because they must. A new battery/new horse is an absolute necessity.

Adherents to reactive maintenance can make seemingly logical arguments for their approach. They waste no time on scheduled maintenance and can just keep working. New equipment routine maintenance schedules are strict and wasteful. It’s more efficient to run something until it breaks than to replace parts when they are good. And so on.

One of the strongest (of all the strong) arguments against reactive maintenance is the safety risk it may pose. A machine might just shut down and need to be replaced or repaired, but it may also cause a secondary failure that injures someone.

A maintenance schedule promotes safety. Prevention of failures—and the risks associated with them—is built into the approach. Moreover, with computer-assisted monitoring of equipment components, predictive maintenance has become a reality.

Sensible action, prudence, a measured approach—all are part of a maintenance schedule.