Offering Wastewater Help

By Diane M. Calabrese / Published August 2020

In Crete in 1700 bc, King Minos installs the first flushing device in a palace wash closet. The flushing—mechanical or not—is the thing. Ever since people could pour a vessel full of water on an accumulation of waste to move it along, they have been flushing. Gravity (if only by the lay of the land) and filters (if only reeds) are also as old as human ingenuity.

Today, science informs efforts to keep waste and water separate. Slated for removal are age-old organic wastes (feces, animal parts) and modern byproducts of human activities, such as nitrates and phosphates from agriculture, pharmaceuticals from urine, and, of course, chemicals and residue from use of a pressure washer.

Collection, recycling, treatment, and reduction are components of dealing with wastewater. Distributors and manufacturers can offer help to their customers with all of these wastewater components.

“All consultations should be presented in a ‘health and safety’ presentation,” says Robert M. Hinderliter, an environmental consultant with a lengthy background and expertise in the industry, who is based in Burleson, TX. “It makes it harder for the customer to refuse to do the job when ‘health and safety’ are at issue…”

It’s not just a better understanding of the array of choices in wastewater treatment that contractors need. They also must have some help with rules.

“How to comply with local environmental regulations” is a tough one, explains Hinderliter. “The rules will vary from jurisdiction to jurisdiction. A lot of the time they seem arbitrary.”

What compounds the problem of rules is that the individuals enforcing the rules may be novices. “Many times, enforcement is by recent college graduates who do not understand the interpretation of the regulations,” explains Hinderliter. “Therefore, they make a literal interpretation of what is written but with little common sense.”

The contractor must take the initiative. That means knowing the rules in the place where work will be done. As a consultant Hinderliter has had the opportunity to work with cities, rural water boards, professional organizations, and others on the development of best management practices (BMPs) for meeting goals of the Clean Water Act (1972). He starts with the premise that BMPs should be “reasonable, rational, and logical”—not arbitrary.

“Understanding how the state EPA establishes standards for local jurisdictions is a must,” says Hinderliter. “This is not readily available information to the contractors or the public.”

How, then, should a contractor proceed? “The only way that I am aware of to find this out is by calling the state EPA office and finding the person who actually is in charge of permits,” says Hinderliter. “Originally, the jurisdictions had to test all of their MS4s, municipal separate storm sewer systems, for pollution. While doing research for the Kansas Rural Water Association, I was surprised to find that Kansas had changed to the TMDL, total municipal daily load, system.”

The change to TMDL affects contractors who use pressure washers. “What Kansas does is to specify where each municipality—jurisdiction—will test for inlet TMDL and outlet TMDL,” explains Hinderliter. “These two are compared to determine what the municipality is discharging. Because mobile power washing is an insignificant contributor to total pollution, enforcement is generally by complaint basis only, but not always.”

Sorting through local and state rules and obtaining permits consumes time. Hinderliter says he would like to see equipment manufacturers think more about how to reduce the cost of equipment used in environmental compliance.

Manufacturers Respond

“Compliance seems to be the biggest concern on most customers’ minds,” says Aaron Auger, water treatment division manager at Mi-T-M Corporation in Peosta, IA. “A wastewater solution isn’t viewed as something people look forward to incorporating into their business plan, but it’s often necessary.”

Bridging the path to a solution is part of Auger’s role in helping customers. “‘What do I need to do to make sure I’m not in violation?’ is usually a large concern of customers, so educating them is important,” he explains. “Once customers understand the solutions you are able to offer, then the rest of the process tends to become a lot easier.”

And the opportunity to help is a frequent one. “This actually happens quite a lot,” says Auger. “Because our company has such a diverse product offering, there have been many occasions where a customer may start out looking for a pressure washer or an air compressor for a wash bay, and the conversation evolves into wastewater treatment.”

Auger’s company has much to offer in response to the unique requirements of the customer. “We are able to provide discharge and closed-loop recycle systems and have been heavily involved in all aspects of construction projects, from concepts to putting up buildings,” he explains.

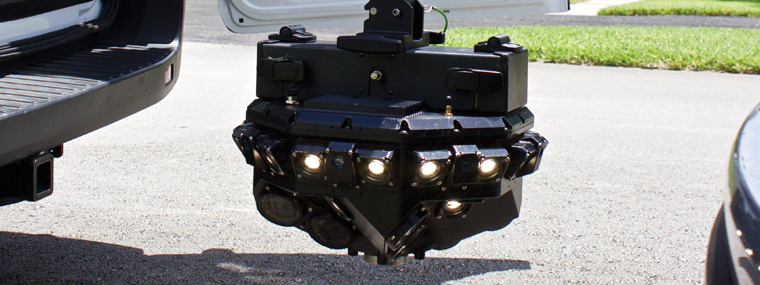

Customer needs have Auger’s company innovating in many ways with new systems set to appear in its product line. “Mi-T-M has two projects that we are set to introduce in the second half of 2020,” he explains. “We have been building undercarriage wash assemblies for a few years now and are going to introduce it as a package system. An automated system that is embedded in the floor that cleans the underside of equipment is a perfect fit for a lot of applications.

“Second, we are introducing a reverse osmosis [RO] system,” continues Auger. “Over the years we have had a number of requests for an RO system to be used along with our reclaim equipment to provide spot-free washing for our customers. The system we will be introducing will be able to be added to an existing reclaim system, ordered with new equipment, or used in a stand-alone application. It will enable us to offer an additional solution for a lot of applications that we may not have been otherwise able to handle in the past.”

Power washing contractors appreciate versatile machines and ancillaries. Similarly, they welcome wastewater solutions that allow them to collect water and more with a single system.

“Wastewater capture on a pressure-washing jobsite has been a challenging problem,” says Ron W. Robarge, the president of Spartan Manufacturing Corporation, whose Pressure Power Systems division manufacturers the Vacu-Boom™ system. And he describes the “total solution” and “time-proven” system for us.

“This system can be used outdoors or indoors for capturing wastewater or other nonflammable liquids and can handle all variables,” explains Robarge. “The system consists of flexible vacuum-operated hollow tubular sections and fittings that can be connected together in different configurations to capture the water and pump it into a holding tank or directly to a legal discharge point.”

Wide-ranging adapters have been served by the system from Robarge’s company and their success noticed. “The system is ideal for pressure washing contractors and for industrial or commercial applications inside buildings where spill control or water capture is necessary,” says Robarge. It is also recommended by environmental regulators nationwide.

Less is More

Twenty-first century pressure washers, car washes, and industrial cleaning processes do more with less water. As such, they generate less wastewater. A lower volume of wastewater is easier to collect and contain.

Some localities may allow certain contractors to discharge the water captured at a jobsite to a sanitary sewer. However, stringent requirements for using sanitary sewers continue to multiply, with pretreatment requirements becoming more common.

Why? If a substance is on the surface of a house, a car, or a machine, it will become part of the wastewater stream. Increasingly, there is the expectation that chemicals used as detergents, grease, oil, pesticides and herbicides, and just plain debris (that in big enough amounts clogs sewers) will be extracted from water before it is sent to an approved holding area or sewer.

Contractors require tools to collect wastewater as well as to complete any pretreatment needed to obtain a permit for disposal. As authorized by the EPA, publicly owned treatment works (POTWs) establish permitting requirements and conduct enforcement in the area they serve. They do so through the National Pollutant Discharge Elimination System (NPDES).

NPDES permitting keeps POTWs (and their users) focused on pollutant reduction. Whether a contractor needs an NPDES permit or not can often only be determined by going through the application process set by a POTW. (The POTW is often, but not always, part of a municipality.)

The ultimate goal of the POTW is to reduce pollutants going into a municipal sewer system. As incremental goals are met, more stringent ones are set. For example, in Kansas, hot water above 110 °F cannot be discharged into a storm drain because it is an emulsifier.

NPDES plans are recalibrated at five-year intervals. In the future expect pathogens of all sorts—not just familiar bacteria—to get more attention.

Wastewater solutions on the horizon will encompass collection, treatment, and on-site reuse to the fullest extent possible. Even the wastes removed from water, including the most hazardous solvents, will one day be recycled.