Mud, Muck, and Grease, Oh My! Cleaning Heavy Equipment

By Diane M. Calabrese / Published December 2022

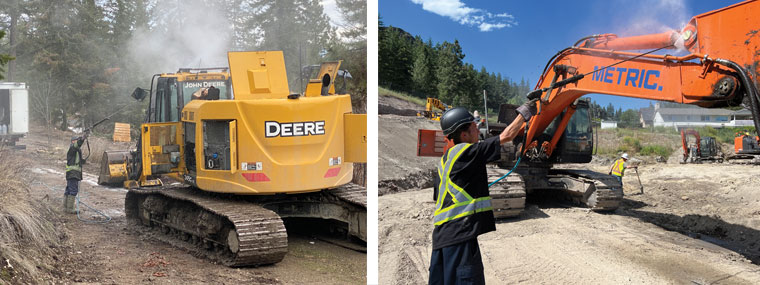

Tracked carriers and mats on substrates are time-tested ways to keep heavy equipment moving across muddy terrain. But no machine can evade the effects of mud forever. Heavy equipment (aka off-road equipment) must be cleaned—just like any equipment.

There’s more than wet or caked-on mud in the mix. “Grease, oil, and grime are tough to clean,” says Karl Loeffel-holz, distributor division manager at Mi-T-M Corporation in Peosta, IA.

So, begin with the correct choice of equipment (hot water and/or steam) and chemicals. “Our hot-water pressure washers and steam units are great for removing these types of soiling,” says Loeffelholz. “We also offer degreasers to help remove these types as well.”

Both off-the-shelf pressure washers and customized equipment are used by contractors cleaning heavy equipment. The “where” of the cleaning determines what’s needed.

“If a portable pressure washing system is needed, we offer a variety of models built with wraparound frames and tires that can be moved from one piece of heavy equipment to the next as well as skid units that can be mounted to a truck or trailer,” explains Loeffelholz.

An enclosed setting is a different matter. “If they’re cleaning equipment in a wash bay, a customized system could provide multiple cleaning stations along with a wastewater recycling system,” says Loeffelholz.

Mike Woolley is the owner of Aqua-Fleet Solutions in Kelowna, BC, Canada. His company, a family business, has been cleaning heavy equipment since 1989.

There is clean, and then there is exactingly clean. Exactingly clean matters. “Fully clean” is what Woolley labels it.

“Many of our competitors simply don’t understand the importance of making a machine fully clean,” says Woolley. “Having an eye for detail is an absolute must.”

In addition, while looking for every part that should be cleaned, it’s imperative to not go too far. “Constantly keeping your eyes open for parts that should not be sprayed is a must,” says Woolley.

“A pressure washer is the most important thing to have in order to clean equipment properly,” says Woolley. “Warm water—not hot—allows the chemicals to work better.”

The correct machine is where successful outcomes begin. “Have the proper equipment and chemicals, and with experience you can wash heavy equipment easily,” says Woolley. “The most difficult stuff to get off is tar.”

Cleaning is about much more than cosmetics, explains Woolley. “Often, I have found broken welds, leaks, and that sort of thing that the operator had no idea of. Cleaning the radiators in a warm climate will help the machine run much cooler as well.”

Nate Farrier, owner of Northern Lightning Wash LLC in Traverse, MI, also emphasizes the significant connection between cleaning and maintenance. “A clean machine, especially a radiator, will operate at a lower temperature and can save costly repairs down the line,” he says.

“Additionally, when any piece of heavy equipment is cleaned regularly, it makes the mechanic’s job easier to spot failures and make timely repairs,” explains Farrier.

Safety gets a boost, too. “By degreasing engines, fires can be prevented, which naturally is very important,” says Farrier.

Challenges

“Consistent pricing is the biggest challenge and is the question I get asked about the most,” says Farrier. The same machine used in different settings will emerge with quite different cleaning needs. Time to clean will vary.

“For example, an excavator working in a swamp in the middle of winter will take far longer to clean than the same machine digging basements in sand in the summer,” says Farrier. “It is always best to actually see the piece of equipment before quoting a price to clean it.”

Sometimes it’s possible to get a look at the equipment prior to giving a price, but sometimes not. If it’s not an option, you can always default to your hourly rate plus materials.

There are substances that challenge more than others. “Concrete removal seems to be the worst,” says Farrier. “Equipment working in quarries can take so much time.” And he emphasizes time.

“As lime or concrete dust floats in the air and lands on the equipment, it will harden, and it needs to be acid washed to be removed layer by layer,” says Farrier. That leads to another challenge.

“Working with strong acids can create other safety considerations,” says Farrier. “Unlike other chemicals, concrete removers tend to require a longer dwell time and multiple applications to give you the desired result.”

There are substantial differences between cleaning heavy equipment and other types of power washing, says Farrier. They begin with water. “It’s common to have to haul your water in from off site,” says Farrier. “Water recovery is a frequent concern.”

Customer demand also has a unique profile. A pause between jobs, or weather so inclement it precludes work, might be when an equipment owner seeks cleaning.

“Logistically, when a customer decides they want the heavy equipment cleaned, they seem to want it all done and in a hurry,” explains Farrier. “That will usually create a bottleneck in manpower and equipment capa-

city, especially during those times.”

Then there is the design of the machine. Chad Lawrence, owner of Chad’s Mobile Wash in College Station, TX, explains that tracks stand out as a particular challenge. “Equipment like dozers or excavators that run on tracks instead of tires can be very challenging to clean thoroughly,” he says.

Such areas get packed with mud/dirt/debris, and if not cleaned often enough, there is a buildup that hardens so much it is rocklike, explains Lawrence. As much of the material as possible must be removed manually before the washing can begin.

Shovels are used to remove as much of the consolidated material as possible. Then it’s application of water and detergents to the actual surface of the machine.

“This can be a very dirty job, is time consuming, and typically takes lots of water—anywhere from a couple of hundred gallons to over a thousand gallons, depending on severity,” says Lawrence.

Greased areas rank alongside tracks as a particular challenge, says Lawrence. Most modern equipment runs on hydraulics, and the equipment has grease fittings located in different areas.

“Using the right detergents and hot water can definitely make this part of the job easier…,” says Lawrence. But care must be taken because even if using cold water only, it is possible to cut through the grease and unintentionally cause more soiling if the grease gets moved around.

“This grease is thick, smears easily, and is not easy to clean,” says Lawrence. If it gets dislodged and blown onto other areas of the machine, the contractor, or the surroundings, it requires a fix of more cleaning time. Overall it’s a dirty job.

Lime, concrete, and asphalt removal from heavy equipment prove to be “by far the most challenging and unpleasant jobs that I have ever had to do,” says Lawrence. “I don’t care what chemicals/detergents you use or if you’re using cold water, hot water, or even steam…”

Know the equipment and the soiling to be removed, explains Lawrence. If it is more than dirt and mud covering the equipment, then choosing the correct chemicals and knowing how to neutralize and handle them are critical to good results.

Methods

Carolyn Fu, outside equipment sales at Carson Team in Portland, OR, views pressure washers and steam cleaners as useful tools when cleaning heavy equipment. She says, “Both pieces of equipment can complement each other very well.”

Not only does Fu’s company sell both pressure washers and steam cleaners, but she brings construction industry experience to her current position. (She is also the daughter of a cement mason.) Fu used that experience to test a hypothesis she had.

“Asphalt and concrete are two of the toughest substances to remove from any surface as they cure,” explains Fu. “I tested a theory with a medium-sized asphalt company that needed help figuring out how to clean their asphalt slurry machines at the end of the day without having personnel spend hours scraping out hardening slurry residue.”

Fu and her collaborators used a hot water pressure washer. Then they used an Optima (Steamericas) steamer. And they found success—a faster and more efficient method—when combining the two in sequence.

“The hot steam lifts the leftover hot asphalt slurry, and the pressure washer blows it out of the machine with very little or no scraping,” explains Fu. The steamer used in the experiment is part of a diverse line of equipment her company sells, a line that includes many brands of pressure washers.

“Hot steam can provide better results in cleaning vehicles and heavy equipment,” says Fu. With more understanding of how the steam machines can function in tandem with pressure washers, and awareness of the cost effectiveness of adding them to the roster, a contractor can gain a strong-serving tool.

“In the transportation and trucking industries, steam cleaning plays an important role in engine cleaning as it helps to release oil, grease, and grit and does not have the tendency to spray removed substances around other parts of the engine,” says Fu. The two-step process of using hot steam to remove caked-on grease and soil before using a hot water pressure washer to wash off the grease and soil works very well.

The bonus in using both steam and a hot water pressure washer is time savings. Fu explains that labor costs decrease when personnel no longer have to spend time scraping sediment from heavy equipment.

Opportunities

Not every cleaning contractor has a big enough team to offer services to construction companies that use an array of equipment. Still, there are opportunities to clean heavy equipment everywhere off-road machines are in service.

On a regional level, evaluate possibilities at farms and landscaping companies. Also talk with equipment rental companies.

The popularity of hydraulic mini excavators is so great—as many as 50,000 sold in the United States in 2021—that companies that might have called in a construction firm to dig a trench or auger for fence poles now take on the work in-house. Contractors equipped to clean heavy machines should reach out to owners of mini excavators.

Yes, business cards are a light year from QR codes. But if a cleaning contractor can give a card to an equipment operator and say, “Call me if looking for someone to clean that machine,” it’s better than dropping a portable device in the muck.