Kitchen Exhaust Cleaning

A Specialty in Demand

By Diane M. Calabrese / Published September 2021

Exacting work, required certifications, state rules, local rules, lots of overnight hours…Kitchen exhaust cleaning is not for everyone, but it is a specialty in demand.

The small thicket of certification, certifying entities, and regulators to navigate should not dissuade anyone. Difficult jobs are often the most interesting.

Is every project closer to cleaning a semiconductor manufacturing plant (say a ‘10’ on the interesting scale) than a concrete driveway (say a ‘1’)? Not at all, says Joey Hilliard, COO/CEO of Hydro-Clean Services Inc. in Beaumont, TX.

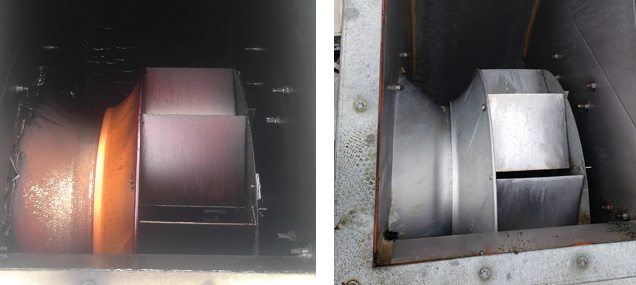

“Each job is unique—some that are a ‘1’ are a cake walk,” explains Hilliard. “Some are a ‘10’—you have to climb inside exhaust ducts and scrape.”

Anything can happen, says Hilliard. Some jobs “turn into an 11-plus.” For instance, his team once discovered building contractors hadn’t properly sealed a shaft—the water pouring from it was the first clue.

“It’s a hard business,” says Hilliard, but not because of the commitment to rigor required. “The thing about hood cleaning is that you have to build a clientele up.”

Hilliard has built a strong business across 30 years. At the start, patience is essential.

Ninety percent of Hilliard’s work is done at night. He does have crews who work at donut shops, some nursing homes, and supermarket chains during the day. It depends on when kitchens are in use.

When we spoke to Hilliard in June, his most difficult issue was finding enough employees. He had two people in training to be supervisors, one truck (out of seven) that had no team to run with it, and prospective customers waiting.

Once hired, team members must be trained and certified. Among the many certification courses offered across the nation, Hilliard likes the one from IKECA [International Kitchen Exhaust Cleaning Association]. “They have a really sound program,” says Hilliard of IKECA. “It has great basics.”

In total, the training for Hilliard’s new team members goes for roughly three months. It includes videos he produced as well as mockups of hoods.

State requirements vary a great deal. [A good place to do a quick check on state rules—and potentially local ones, too—is at the USA.gov website.] To cite one example, some jurisdictions will specify how wastewater is to be collected, whether it is to be filtered or hauled away, and so on.

When Hilliard’s team has completed cleaning an exhaust duct system, the system receives a sticker indicating that it meets the expectations established in code 96 of the NFPA [National Fire Protection Association]. NFPA establishes protocols not only for how exhaust systems should be cleaned but also how often they should be inspected for grease buildup.

Since 2009, IKECA has worked with ANSI [American National Standards Institute] as a standards developer. The NFPA is also an ANSI organization.

Most state and local regulators set rules for cleaning and inspection that derive from NFPA 96. And most give options regarding how individuals can be trained and certified in kitchen exhaust cleaning.

NFPA 96 is a standard that encompasses minimum safety requirements for design, installation, operation, inspection, and maintenance of public and private cooking operations. Restaurateurs and operators of institutional kitchens will be well versed in the expectations they must meet. Contractors entering the kitchen exhaust cleaning sphere will be immersed in the standard after taking a certification course.

Joe Palmore, the CEO of Grease-Busters in Rockville, MD, is also one of the founders and a board

member at United States Academy for Kitchen Exhaust Specialists (USAKES), which was established in 2012. USAKES trains and certifies technicians in commercial kitchen exhaust service, fire suppression, and safety compliance inspection. A fire marshal teaches courses.

The USAKES course is ISO 9001 certified. Whichever course a contractor seeking certification chooses, he or she will likely meet fire marshals, who often become involved in instruction. The link is valuable because fire marshals have all too often seen the disastrous results of insufficient hood cleaning.

“We’re the only company that does on-the-job training,” says Palmore. “You don’t have to join our organization to take a course in cleaning.”

The necessity for cleaning to come from outside of the restaurant for kitchen exhaust cleaning ensures there is a clear demarcation between cleaning and inspection. As for a do-it-yourself approach to cleaning kitchen exhaust, it is not an option. “By law, it cannot be done in-house,” explains Palmore.

Indeed, the kitchen exhaust cleaning sector of our industry has grown in concert with stricter rules for restaurants and other facilities with kitchens. Palmore explains there was a time when kitchen owners did their own cleaning, and the self-appraisal was not always sufficiently candid.

“Insurance companies stepped in,” says Palmore. In short, in an effort to lower risk, insurers set NFPA 96 as the protocol to be met.

Palmore’s own company handles many contracts for the federal government. He also franchises, and, like our other sources, he is a firm advocate for rigorous training. Proper techniques documented by certifications elevate professionalism and improve safety. So do inspections.

NFPA 96 sets the exhaust system inspection schedule for restaurants as quarterly. Other facilities where kitchens are in use—e.g., churches—generally have a lower frequency of required inspection, perhaps annually if volume of cooking is low enough.

Systems tied to solid fuel cooking operations must be inspected monthly. The inspection schedule to which a kitchen’s operator must adhere will give a contractor a good idea of how often the exhaust system must be cleaned. There are big contracts available across the country for contractors who meet certification and licensing requirements.

Getting It Right

Before enrolling in any third-party course for training, a contractor should be certain the training meets the requirements of the locale or locales in which he or she will be working. “He or she will be required to be certified in many jurisdictions,” says Paul Schneider, owner of Ability Services in Champaign, IL.

“In Las Vegas, for instance, you have to work with a licensed company for a number of years before qualifying to take certification training,” explains Schneider. As other examples, he cites Massachusetts and New York City as “very restrictive” and Indiana and Louisiana as “much less restrictive.”

Schneider suggests a good place to begin is by contacting the local fire marshal about fire codes in use and levels of certification needed. When choosing a course/school, be sure to understand whether it trains exclusively or does training as well as certification and testing. He recommends UAMCC [United Association of Mobile Contract Cleaners] as a possibility.

Beginners should get hands-on field training, says Schneider, who has written a manual and produced a video for training his employees. Following learning from manuals and video, the trainee is taken into the field with a professional who serves as a mentor to him or her as hands-on skills are honed.

“I have trained quite a few would-be hood cleaners the same way, and most have become successful,” says Schneider. He adds that he has also written a manual that includes marketing, administration, and sales advice for the start-up hood cleaner.

“Whomever one chooses to train with, realize that you have moved into the fire protection arena, and that the job needs to be done correctly because lives and property are at stake,” says Schneider. He emphasizes that is not a statement of deterrence.

“In spite of regulations about required training, kitchen exhaust cleaning is a very doable business, by itself or as an add-on service,” explains Schneider. “One of my trainees who operated a power wash business has built up so much hood-cleaning business that he has dropped all but the most profitable power-wash contracts…”

Moreover, Schneider stresses the third-party nature of the cleaning. “Most commercial kitchens are required by local officials and their fire insurance providers to have kitchen exhaust cleaning done by a contractor rather than in-house. Very few have the technical know-how to do it themselves.”

Several degrees north of the Lone Star State, Schneider’s experience in the Land of Lincoln over the last year parallels that of Hilliard. Although his was deemed an essential business, many of Schneider’s customers—restaurants in particular—were closed.

“We had to lay off for a few months, but now we have more work than we have employees for,” says Schneider. “There is a waiting list now for my services. Others in the industry are in the same situation. In my view, it is an excellent time for a power washer to add this service on.”

Hilliard’s experience across the daunting interval that began in early 2020 is similar with an added twist. “We had two hurricanes, COVID-19, a flood, and a freeze in the same year,” he explains.

“Once the restrictions started lifting, everything started shooting up,” says Hilliard. “We’ve been very blessed. Ninety percent of our customers came back.”

For those thinking about leaping into kitchen exhaust cleaning, we add this point: On the 1 to 10 scale of difficulty, 10 being the most difficult, Schneider put most jobs at a 7, while Hilliard and Palmore put most jobs in the 6–7 range.

Building a relationship with clients is something kitchen exhaust cleaners do naturally. Visiting establishments some three times a year, even in off hours, gives a contractor the opportunity to make suggestions to the owner.

A type of suggestion most owners welcome is how to make facility care easier on everyone. What if it were possible to impart some resistance to grease build-up in kitchens? It is.

Brad Van Cromvoirt, CEO of WorldWare Enterprises Ltd. in Kitchener, ON, gives us one example. It is the product BT200™, which is trademarked by his company. The product can be used to clean spray vents in commercial kitchens.

One adopter of the product developed a proprietary process that delivers the product in a mist. The technique allows oil vapor to be captured. The less oil vaporized, the less oil to settle on hoods and vents.

In commercial kitchens in general, the product from Van Cromvoirt’s company can be used to clean floors and drains. Because it is a microbial-based product, the microbes keep working for 72 hours. In essence, the microbes use the grease (oil, fat) as a food source and break down the material to carbon dioxide and water.

The most significant factor for kitchen exhaust cleaners is the long-term value of repeated applications, says Cromvoirt. “The more you use the product, the less you need.”

Contractors who tackle kitchens welcome products that speed their efforts, such as the microbial-based one Van Cromvoirt’s firm offers. And if there is one thing that kitchen owners appreciate, second only to a cleaning job completed in an excellent way, it is the minimization of time the kitchen must be out of service while being cleaned.

Finally, keep in mind NFPA 96 is only the starting point in kitchen exhaust cleaning. (Grease gets the attention of the Environmental Protection Agency and efficiency concerns the U.S. Department of Energy.) It’s demanding, but it’s profitable.